Optimization of Bipolar Plate Machining Process Using the Taguchi Method on CNC 3-Axis

DOI:

https://doi.org/10.59511/riestech.v4i01.140Keywords:

Bipolar Plate, Machining, Taguchi Method, OptimizationAbstract

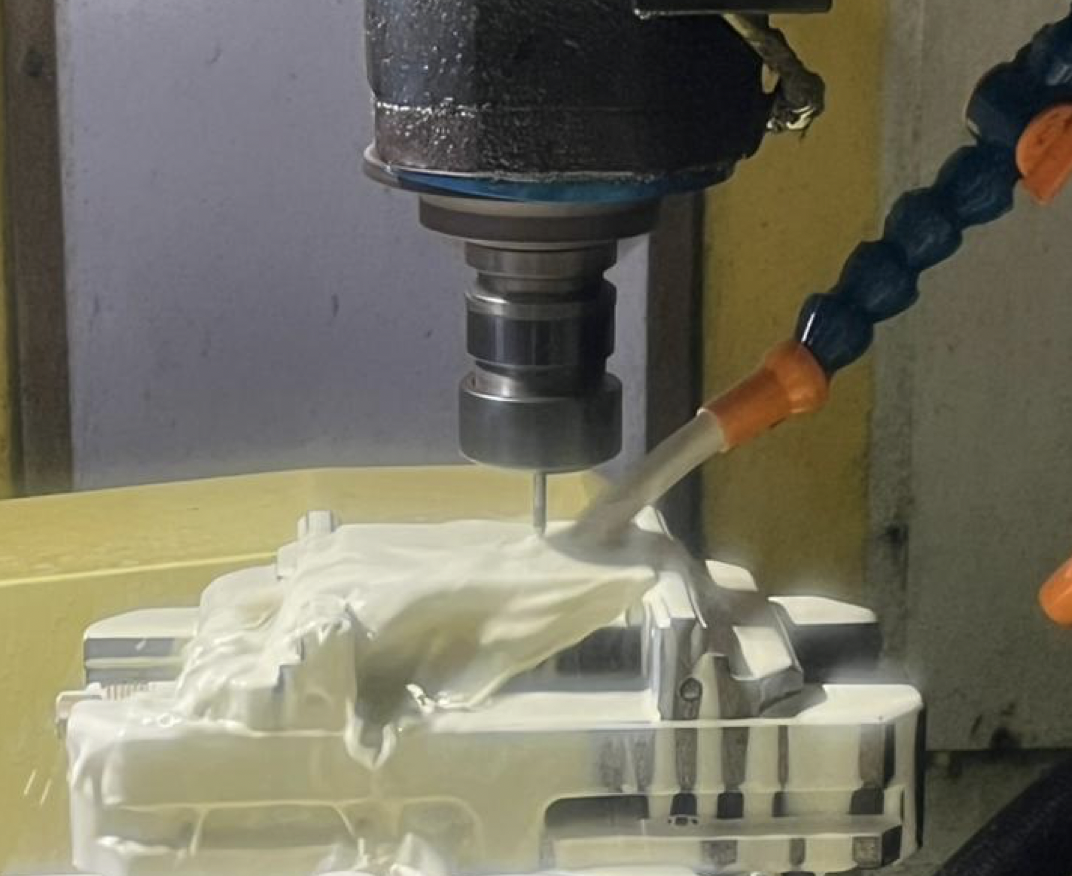

This study aims to optimize the machining parameters of bipolar plates using a CNC 3-axis milling machine based on the Taguchi method. Bipolar plates play a crucial role in proton exchange membrane fuel cells (PEMFCs), where dimensional accuracy and surface quality directly affect cell performance. The machining parameters considered in this research include spindle speed, feed rate, and depth of cut. An L9 orthogonal array was selected to design the experiments, and surface roughness as well as material removal rate (MRR) were evaluated as performance characteristics. Signal-to-noise (S/N) ratio analysis was applied to determine the optimal parameter combination. The results show that spindle speed and feed rate have the most significant influence on surface roughness, while depth of cut mainly affects the MRR. The optimal setting obtained was 3500 rpm spindle speed, 300 mm/min feed rate, and 0.2 mm depth of cut, which produced the lowest surface roughness and acceptable MRR. The confirmation experiment validated the Taguchi model prediction with an error of less than 5%. These findings demonstrate that the Taguchi method is an effective tool for optimizing CNC machining parameters of bipolar plates, improving both quality and manufacturing efficiency.